Month: April 2014

Using sept 2013 recipe base with salt additions:

- 6kg Gladfield pilsner malt

- 300g gladfield gladiator malt

- 300g gladfield medium crystal malt

- 7g Gypsum

- 2g CaCl

- 20g 6.7% motueka – first wort hopped

split half in mash, half in sparge water.

pH not temp adjusted, reading 5.2

Ph measurement was spuradic – reading current from the mash tun – needed to draw off sample to read

Mashed at 66c for 90 mins, mashed out to 72c, sparge ater 76c

pre-boil gravity – 1.074 ! – Need to lower

3l – IPA boil – top up with 500ml water

3L – New world boil – top up with 500ml water

Add 2L 55c water for to main boil temp dropped to 96c

match sparge pH 7.7 to 5.28

added .6g citric acid to bring to 5.1

New world &NZ pale Ale 5 L

- 3omin 8g wakatu 6.8%

- 15 mins 8g Riwaka 5.6%, koppa floc

- 0min 8g Riwaka 5.6%

Ipa – 5l

- 5g Simcoe 12.9% 30 mins ipa

- 15 mins 8g Riwaka 5.6%, koppa floc

- 0 g 8g Riwaka 5.6%

- Ipa 5L – 1.074 – will need to dilute

Pale ale

- 15 Mins 10 g, Riwaka 5.6%

- 2g koppa floc

- 1 L carafe and 1.5L carafe

- Pale ale 1.050 OG

Belgian Blonde

- 2.2g orange zest

- 5g corriander.

- 100g cane sugar,

- 100g sugar syrup

- 1.050 og

- 14L – blue water fermentor

New World 1.070

Pitched 3 nov fob fruit ongoing into Belgian

Swartzbier s05 into Pale ale, IPA

Castle pub tap

Bottling

Belgian bruin

Keg

500mlx3 2.2ml syrup

1.004

Rich coffee notes, very dry finish

Schwartzbier

1.014

Dark ale 10.1

750

500

Smooth

Esb 4.2

1.012

Keg

500

750×3

Little bit ash tray

Bitter 4.1

1.010

Keg

500

750×3 3mls

Smooth with bitter finish – too bitter? Malt lacking?

Strong

Strong esb

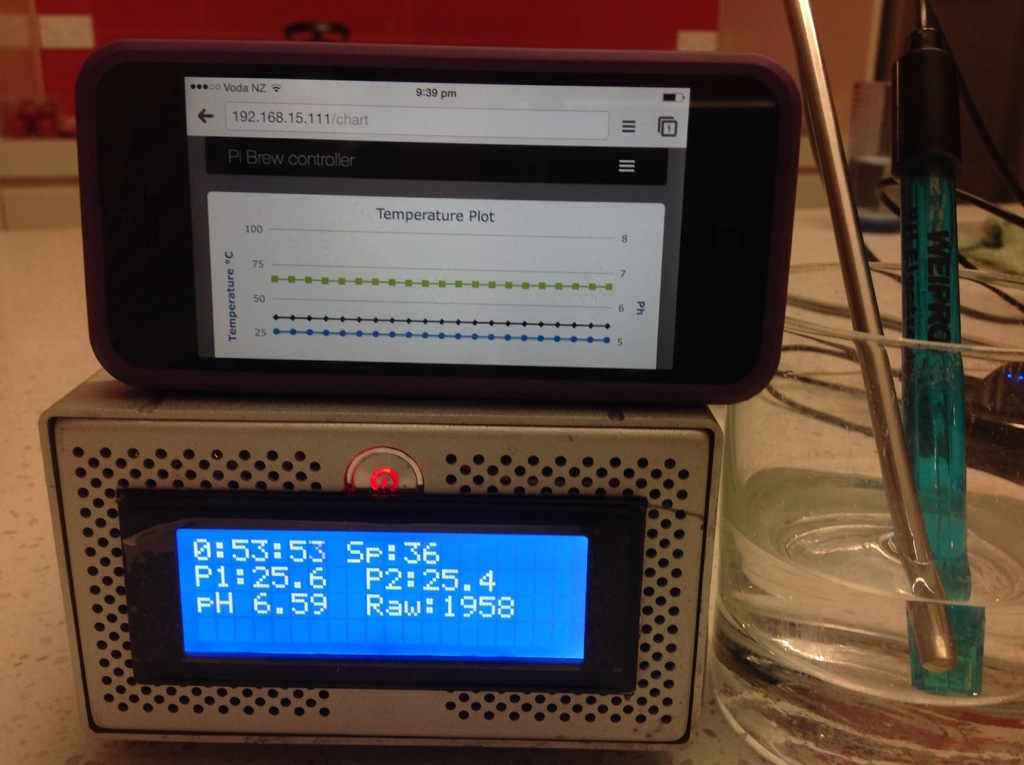

Mash controller housing

2014 Perry

Leah kindly dropped off 3 boxes of pears from her grandfather.

20L yield from the juicer.

Also used Ellen’s steaming juicer, approx 2L of syrup, plan to back blend this after fermentation.

Wrote off another hydrometer, gravity 1.040

8 apr 2014

Rehydrated mangrove jacks m02 cider yeast in water

25 may 2014

Bottled fg 1.012

30 grolsh bottles 455ml

Carbed with 2g syrup;

Re-programme an stc-1000 v1.0 with customer brewing firmare, that supports temperature gradient profiles.

The STC-1000 is a dual stage (heating and cooling) thermostat that is pretty cheap to buy. I (and a low of fellow homebrewers) use them to control the fermentation temperature of beer.

The goal of this project is twofold

To create the means to reprogram the STC-1000 with a custom firmware

To create a custom firmware, suited for fermenting beer

The first goal is achieved by using an Arduino UNO with a sketch to act as a programmer, and the second by using the SDCC compiler and GPUTILS.

Download by visiting the releases page and start by reading usermanual.pdf

Features

Both Fahrenheit and Celsius versions

Up to 6 profiles with up to 10 setpoints.

Each setpoint can be held for 1-999 hours (i.e. up to ~41 days).

Somewhat intuitive menus for configuring

Separate delay settings for cooling and heating

Configurable hysteresis (allowable temp swing) from 0.0 to 2.5°C or 0.0 to 5.0°F

Approximative ramping

Button acceleration, for frustrationless programming by buttons

Cheers!

Updates

Source code:

https://github.com/matsstaff/stc1000p

Discussion Thread:

http://www.homebrewtalk.com/f51/stc-1000-a-464348/

User manual:

usermanual.pdf